Manufacturing

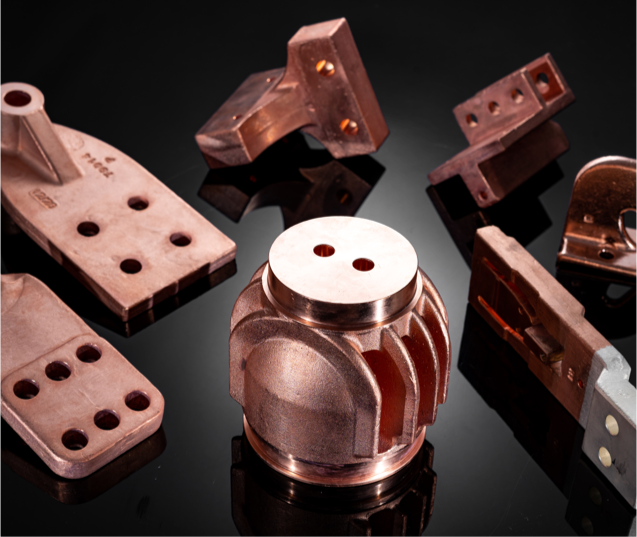

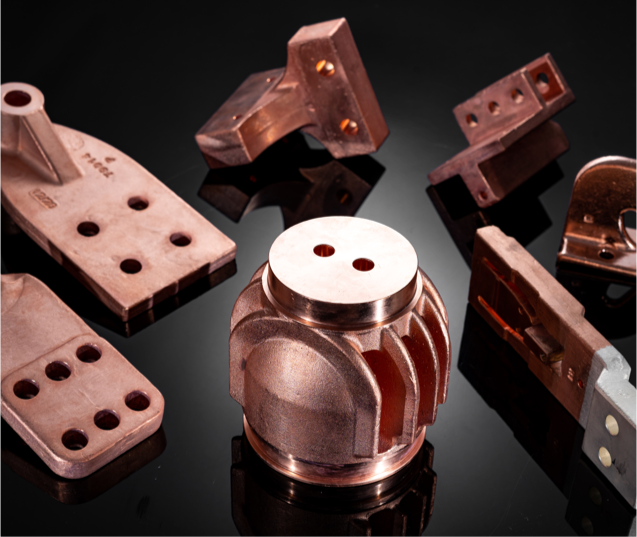

Foundry

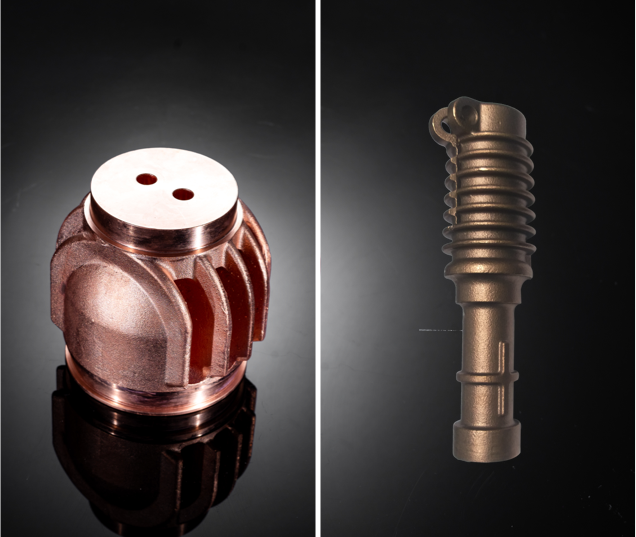

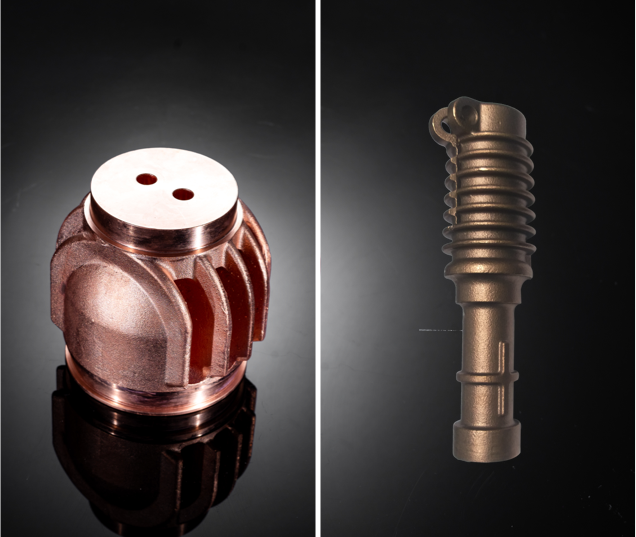

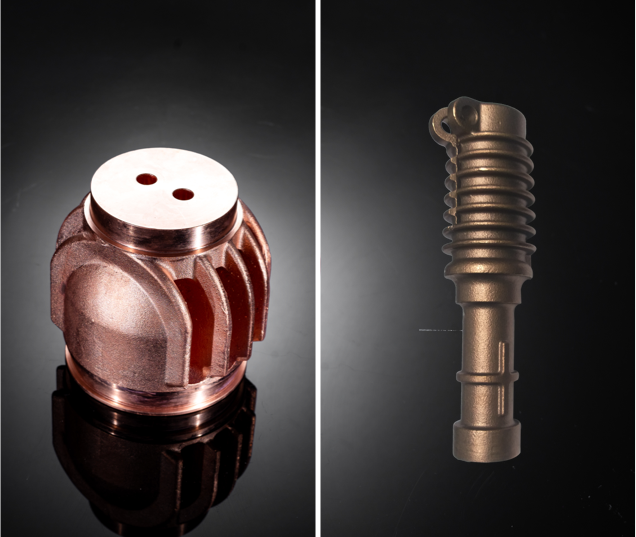

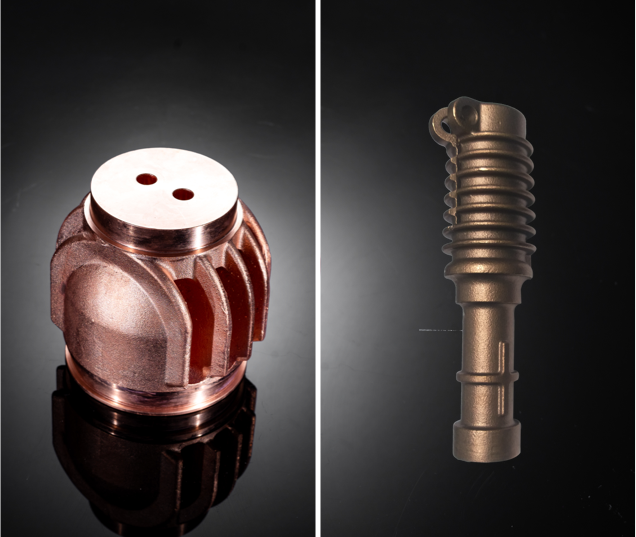

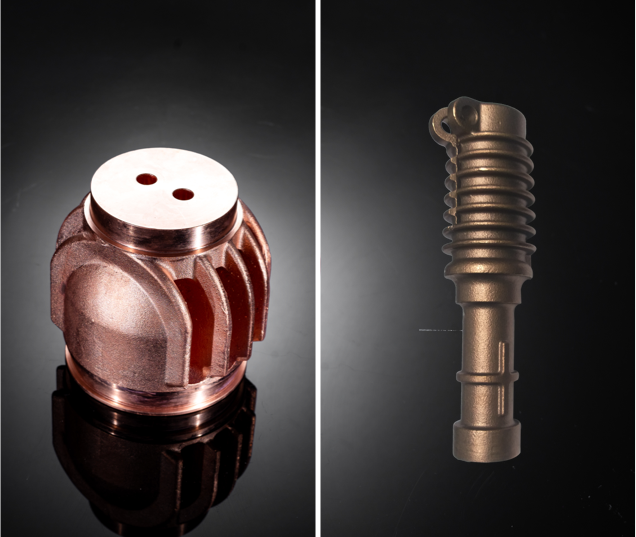

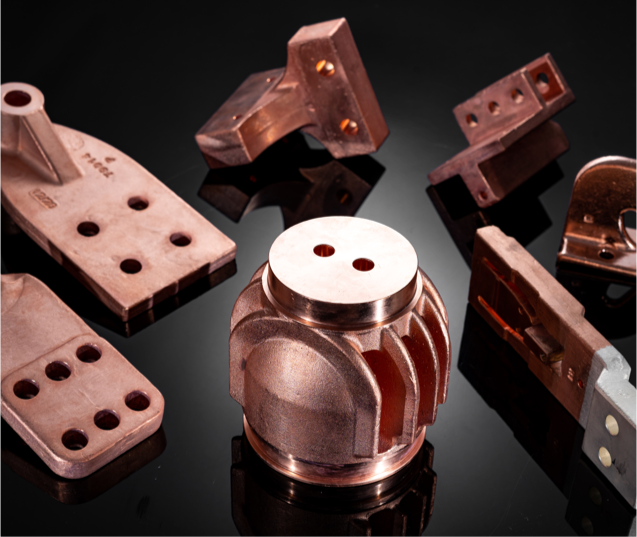

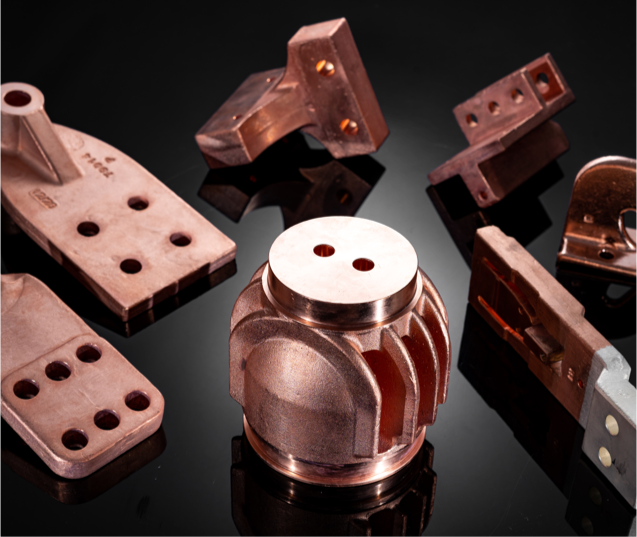

Depending on the material, we use a wide range of foundry processes to achieve high-end results, including:

Permanent Mold Casting (Permold)/ Gravity Die Casting

Permanent mold casting is a type of foundry process used to manufacture castings in bulk, by using permanent metallic reusable molds. The result is dimensional stability and superior surface finish. The process produces a strong casting with smooth surfaces, and little or no defects.

The mold, also known as a die, is created using highly durable materials that can withstand many thermal cycles. More importantly, it is a custom process that saves time and money, inevitably becoming the preferred choice of several customers.

The Process

Depending upon the metal casting business, the permanent mold chill casting process is broken into four key steps — creating the mold, pouring molten metal into the mold, cooling the metal, and opening the cast.

1

2

3

4

The permanent mold manufacturing process requires special design capabilities. Rapsri has an in-house R&D team equipped with manufacturing capabilities for high-end permanent mold design based on solidification simulation.

The Advantages

Continuous Casting

Given the high demand, tubes and solids are the most commonly manufactured continuous casting shapes. However, shapes such as squares, rectangles, and hexagons can also be produced based on customer requirements.

The Process

Molten metal from an induction furnace is fed into a mould with the required shape.

1

2

3

4

5

The Advantages

Sand Casting

Sand casting is the most versatile among manufacturing methods, and opens up a range of possibilities. One of the advantages of using this method is that several metals and alloys can be chosen to form the cast parts. In this process, molten metal is transferred into an expandable sand.

We collaborate closely with reliable foundry partners to provide sand casting solutions.

The Process

Our shell molding process coupled with RAPOUR pouring technology gives the best combination of physical and mechanical properties with very high casting integrity. RAPOUR technology ensures a fine grain structure and microstructure comparable to the chill cast process. Good surface finish and close dimensional tolerance reduce the need for machining and preserve the aesthetics of a cast finish.

Besides, we also collaborate closely with reliable foundry partners to provide advanced sand casting solutions.

1

In the mould making step, the mould makes a cavity in the sand which exactly matches the form to be produced. The sand is usually bonded to a metal part, called a cope and drag.

2

In the clamping step, the cope and drag halves fit together to form a tight seal.

3

4

5

6

In the seventh and final step of trimming, the finished product is cleaned, and all extra projections are removed.

7

The Advantages