SUSTAINED

FOCUS ON RESILIENT

INNOVATION

We transform businesses across a wide range of industries by engineering solutions with quality precision. Our focused approach towards research, innovation, and development has helped us manufacture cutting-edge products that meet exacting international standards.

Our R&D department, headed by Dr P Sriram, consists of experienced researchers who collaborate with the operations team for determining critical market needs. This focused approach has resulted in material inventions, process inventions, application engineering, and design to prototype.

We have invented several materials over the last five decades to satisfy the unique needs of our customers. Here are some of those dramatic solutions that we have manufactured over the years.

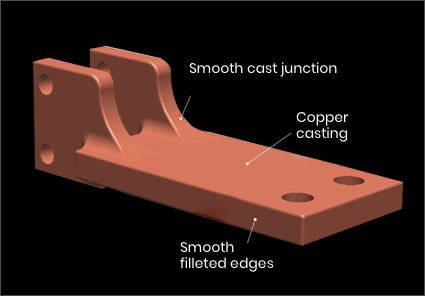

High-conductivity

cast copper (99% IACS)

The call for green energy has led power transmission and distribution segments to focus on heat rise for switchgear and circuit-breaker designs. When manufactured through the traditional process of sand casting, electrolytic cast copper contains 75-85% IACS. However, our R&D team has developed a melting and refining technology that helps us deliver cast copper with 99% IACS — both in sand casting and permanent mold gravity die casting processes.

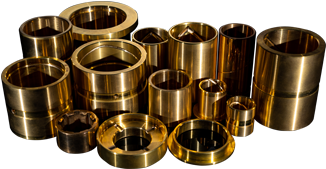

High-strength lead-free alloy (RB031)

Our processes are driven by key factors such as cost, product performance, component quality, and environmental commitments. We either invent new processes or make significant technological changes to existing ones to stay ahead of the curve.

Rappour process for sand casting

In pure copper, the melting and pouring process produces conductivity of 99% IACS. Our team has developed a method for delivering sand casting with superior mechanical properties that is close to the theoretical density.

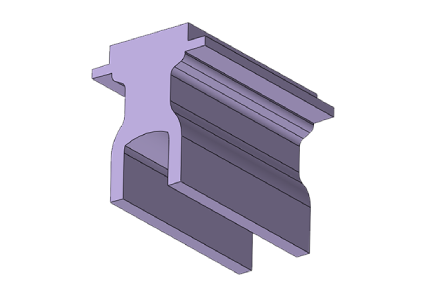

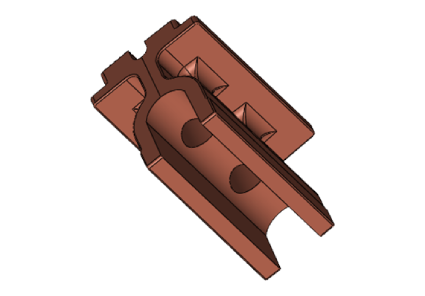

Permanent mold/gravity die casting

In the 1970s, we were one of the two inventors in the world to develop a permanent mold or gravity die casting process, which was commercialised during the late 1990s and early 2000s. Since sand casting is not eco-friendly, we have been using permanent mold or gravity die casting to manufacture copper and high-copper alloys. Our process contains certain unique features that differentiate us from our competitors.

We are one of the few companies in the world that uses this process for:

- Improving mechanical properties and physical properties

- Diversifying into different markets to substitute existing technology (such as forging, extrusion, and brazed assemblies)

Anti-tarnish silver plating

Our team has developed a proprietary process that prevents copper casting which is electroplated with silver from tarnishing and developing blue or green discolouration in the long run. This innovative technology helps us deliver high-quality plated components to our customers globally.

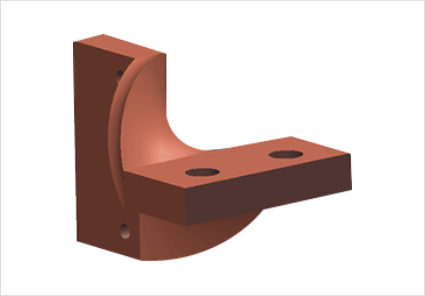

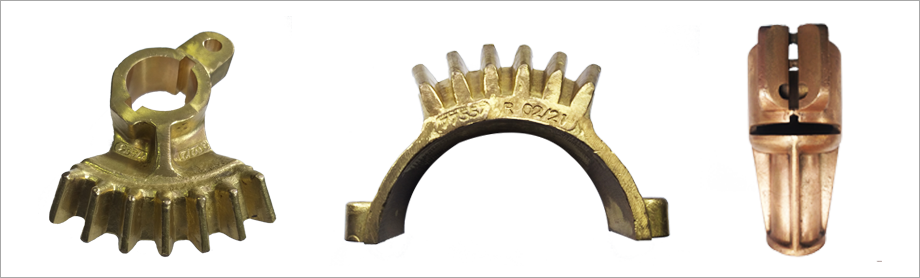

- Copper fabrication converted to single-piece cast component

- Excellent and uniform electrical conductivity achieved

- Heat treatment eliminated

- Overall cost reduced

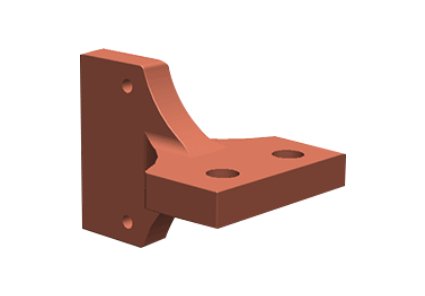

- Extruded part converted to cast part

- Weight reduced

- Machining process eliminated

- Overall cost reduced

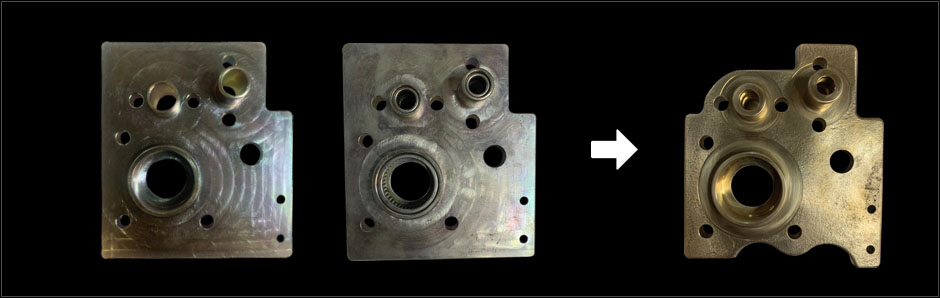

- Steel casting with bearings redesigned as brass casting in RB031 alloy

- Bearings eliminated

- Bearing assembly and additional process eliminated

- Overall cost reduction

The above parts are references of converting from sand casting to permanent mold casting, providing the

following benefits to our customers:

- Good surface finish and aesthetics

- Better dimensional stability

- Casting soundness

- Cost reduction

- Fabrication with brazed joints converted to single-piece casting

- Excellent and uniform electrical conductivity achieved

- Weight reduced

- Overall cost reduced

Our advanced research and development team uses state-of-the-art equipment to simulate, design, and build prototypes for machined components as per the client’s requirements. The entire process occurs at different stages where a thorough simulation is conducted once before initiating the design process. Also, the deliverable parts are thoroughly inspected for quality before they are shipped to our customers.

Simulating, Designing, and Drafting

Plating parts

Non plating parts

Receive development order from marketing

Input study

Pre-development CFT meeting

Plan sequence of process, start date, end date, budget, and source requirements

Convert customer drawing to Rapsri drawing

Design and drafting

Tools manufacturing

Procuring production aids and WI preparation

Tool inspection

Pouring

Fettling

Inspection

Machining

Electroplating

Final inspection

Packing and shipment

Receive Development Order from Marketing

Input study

Predevelopment CFT meeting

Plan sequence of process, start date, end date, budget and source requirements

Convert customer drawing to Rapsri drawing

Design and Drafting

Tools manufacturing

Procuring production aids and WI preparation

Tool Inspection

Pouring

Fettling

Inspection

Machining

Plating

Final Inspection