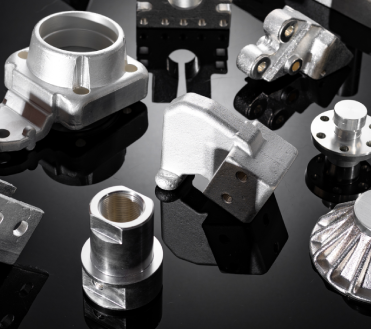

Manufacturing

ELECTROPLATING

Delivering high-quality electroplating

Our advanced manufacturing facility delivers high-end electroplating processes for a wide range of industrial applications. With over decades of combined experience, we provide the highest level of commitment to superior quality and performance for all our products.

Silver Plating

Our plant is capable of plating silver on varied machined components – from simple to complex geometries, including blind holes. We ensure that the highest quality is maintained throughout the plating process by using

We also ensure the required thickness of the plated components by active measurement at our XRF test facility.

Tin Plating

We offer tin plating in matte finish for a wide range of components – from simple to complex geometries, including blind holes. Our team conducts regular checks for superior quality and finesse by ensuring that our matte finish-plated electrodeposits are crystalline and silvery white, with two component brighter systems.

Nickel Plating

With strict adherence to ISO standards, we provide nickel plating for a wide range of copper and copper alloy castings – from simple to complex geometries as per customer requirement. Our nickel plating delivers a unique combination of corrosion resistance, lubricity, reflectivity, and electrical conductivity. This produces a hard nickel plating deposit that enhances wear resistance, especially for sliding contacts.

Additionally, we check the plated castings for quality parameters, like adherence by thermal shock test, and thickness by non destructive XRF test facility.

Partial Plating and Dual Plating

Partial plating involves masking the component with a special masking compound that withstands corrosive action of hot alkaline and acid solutions/chemicals, used in pre-cleaning operations and plating processes.

We apply PVC masking compound by brushing, dipping, or spraying on the component. Further, we dry the component and conduct silver plating with suitable jigs to avoid contact marks on the components. Once the plating process is completed, the masking compound is peeled or removed from the components and the plated parts are cleaned suitably.

Dual plating involves plating of two different materials (eg. silver and tin) on different surfaces of the same component. This involves necessary masking prior to the plating process and de-masking after the process.